Automatic Tube Cleaning System (ATCS)

Keep your Water-Cooled Chiller Condensers are running permanently at their peak efficiency:

Together with our partner ParSam Techsolutions Pvt. Ltd. (India) we make Automatic Tube Cleaning System (ATCS) is a unique hydro-mechanical cleaning system that operates continuously to keep heat exchanger tube internal surfaces completely free from fouling. Fouling in the Condenser / Shell & Tube Heat Exchanger is a huge Energy Guzzler that is among the most overlooked energies wasters in our economy. Up to 60% of the energy used in commercial buildings is attributed to HVAC systems, which consume almost 40% of the nation's total energy consumption. System optimization is now more important than ever for improving cost efficiency, reducing resource consumption, and improving environmental quality. The chiller is a critical component of HVAC systems and process cooling systems in commercial and industrial buildings. Despite being highly efficient, pervasive tube fouling prevents the full optimization of Water Cooled Chillers. Research shows that just a 0.6mm scale layer on condenser tubes reduces chiller heat transfer by 34% and increase energy consumption by 21%. Because there were no alternatives, it was overlooked and minimized or eliminated by manual cleaning by technicians for over a generation.

Problem on Fouling in Heat Exchanger / Condenser

Fouling is a common problem in condensers and shell and tube heat exchangers that can affect their efficiency and performance. Fouling occurs when suspended and dissolved solids, such as minerals and organic matter, deposit on the surface of the tubes and reduce their heat transfer capabilities.

Example Increases in Energy Consumption as a Function of Scale Thickness

1/32" scale = 08.50% increased energy consumption

1/16" scale = 12.40% increased energy consumption

1/80" scale = 25.00% increased energy consumption

1/40" scale = 40.00% increased energy consumption

The U.S. Department of Energy. Non-Chemical Technologies for scale and Hardness Control. Technology for improving energy efficiency through the removal or prevention of scale.

Are you tired of frequent shutdowns and costly maintenance of your cooling systems?

Keeping your Chiller Condenser in pristine condition is crucial for both quality and efficiency. Traditional manual cleaning methods may be time-consuming and unsustainable.

Say goodbye to those pesky debris and scales that clog your condenser tubes with our “Automatic Tube Cleaning system”

Here we introduce our Automatic Tube Cleaning System: “Engineered for everlasting performance”

This innovative solution utilizes sponge balls and water to clean industrial equipment without the hassle of manual scrubbing. Our system is designed to clean your condenser tubes thoroughly and efficiently without any manual intervention.

ATCS is Designed and developed in India to survive in the most difficult situations. Keys to producing an incredibly reliable and consistent system that will survive for a very long time are fabrication accuracy and component quality.

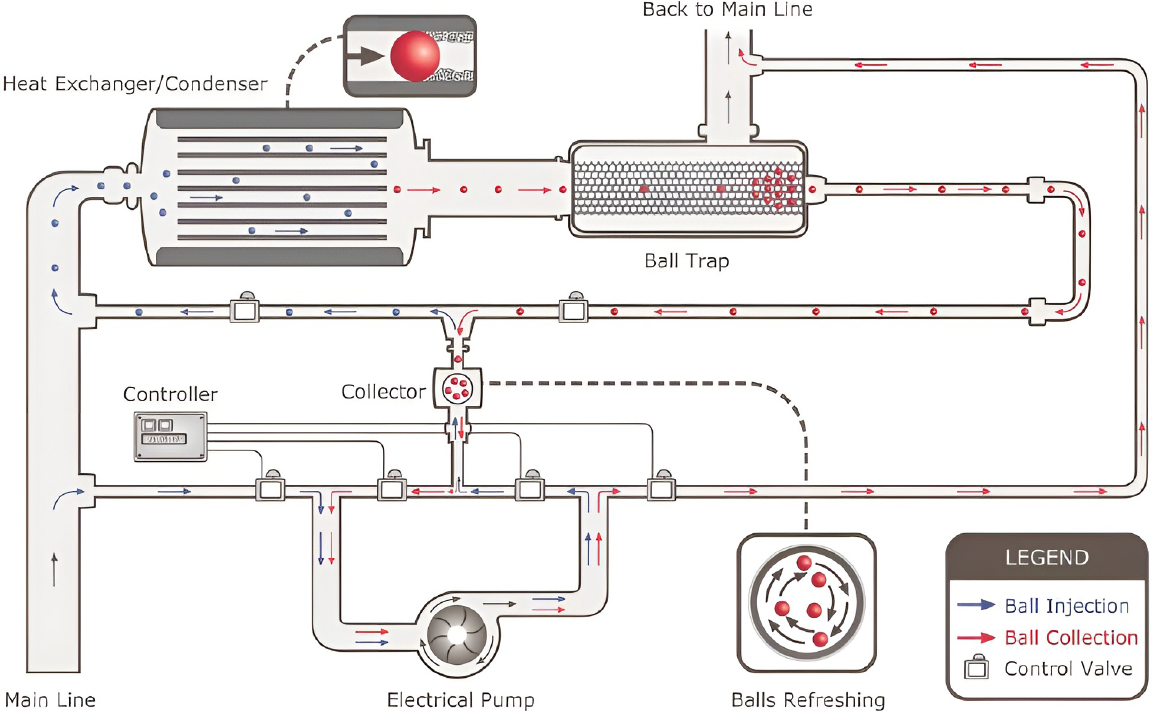

How does the ATCS Works?

The Automatic Tube Cleaning System continuously and consistently cleans heat exchanger tubes by circulating sponge balls through the tubes at pre-determined intervals, prevent build-up of residue, deposits and biofilm in the tubes. The Sponge Balls are slightly larger in diameter than the tubes, and wipe the tubes clean as they pass through. The Sponge Balls are then trapped on the heat exchanger outlet line where they are collected, forwarded and stored until the start of the subsequent cleaning cycle.

Interested in our services? We’re here to help!

We want to know your needs exactly so that we can provide the perfect solution. Let us know what you want and we’ll do our best to help.